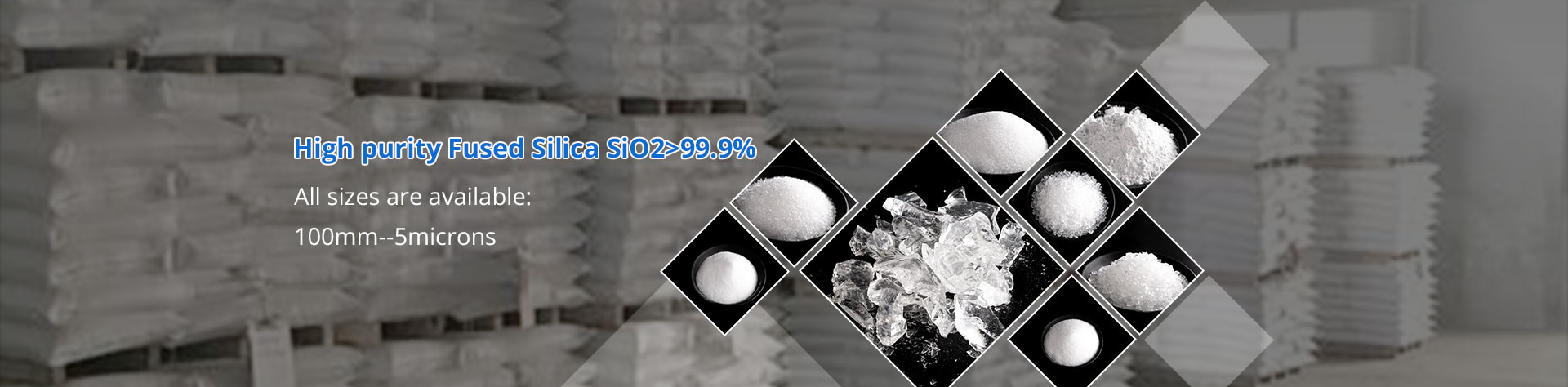

Products >> Fused silica for tableware >>

fused silica for tableware ceramic

- Product No.:click for details

- Price(USD):500

fused silica ceramic can be made of high purity fused silica sand,fused silica powder which spec is as follows:

SiO2>99.9%,Fe2O3<30ppm,Al2O3<100ppm,Na2O+K2O<60ppm.

4-10mesh,10-20mesh,30-50mesh,50-100mesh,-100mesh,-120mesh,-200mesh,-325mesh.

SiO2>99.9%,Fe2O3<30ppm,Al2O3<100ppm,Na2O+K2O<60ppm.

4-10mesh,10-20mesh,30-50mesh,50-100mesh,-100mesh,-120mesh,-200mesh,-325mesh.

Chem&size Minerals Fused Silica is high purity quartz sand which has been melted to amorphous silicon oxide(glass phase) by

electrically fusing (fusing temperature 1800-2200ºC), then specially engineered into sand/grains/granular or powder/flour form.

The characters of fused silica is as follows:

1).fused silica characterized by the lowest thermal coefficient of expansion (0.54×10-6ºC-1,0~1000ºC),high resistance to

temperature and thermal shock.

2).high Purity (high SiO2 content 99.96%, low Fe, Na, K and Ti)

3). Statistically controlled particle size distribution

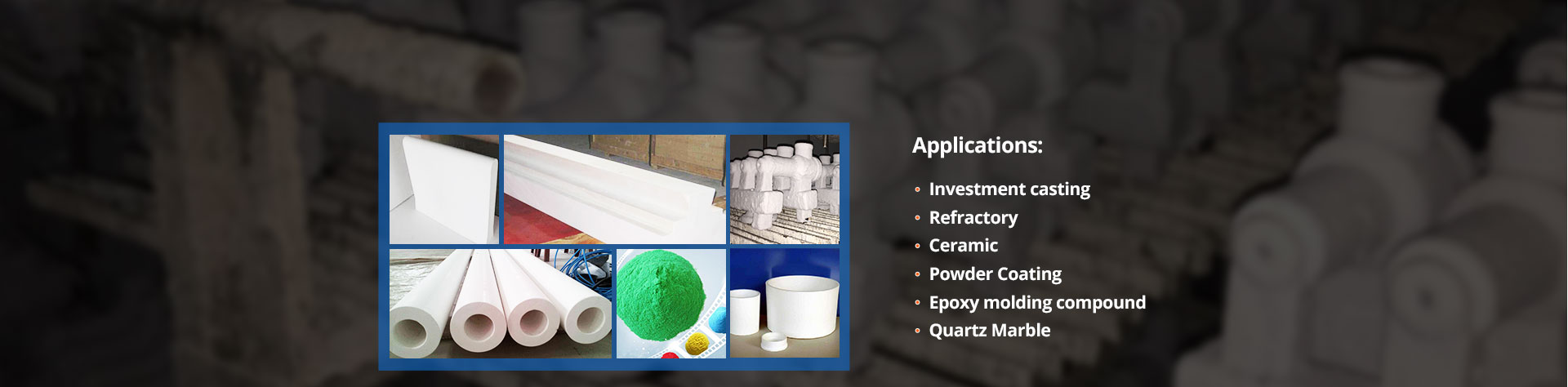

Fused silica main Applications is used to make Fused Silica Roller and other High Temperature Technical thermal Ceramics.

electrically fusing (fusing temperature 1800-2200ºC), then specially engineered into sand/grains/granular or powder/flour form.

The characters of fused silica is as follows:

1).fused silica characterized by the lowest thermal coefficient of expansion (0.54×10-6ºC-1,0~1000ºC),high resistance to

temperature and thermal shock.

2).high Purity (high SiO2 content 99.96%, low Fe, Na, K and Ti)

3). Statistically controlled particle size distribution

Fused silica main Applications is used to make Fused Silica Roller and other High Temperature Technical thermal Ceramics.

| 1 | Physical Properties | |||

| 1.1 | Composition | SiO2 | ||

| 1.2 | Structure | Amorphous | ||

| 1.3 | Colour | Transparent or white | ||

| 1.4 | Melting Temperature | approx.1750ºC | ||

| 1.5 | Specific Gravity | 2.21g/cm3 | ||

| 1.6 | Hardness | 7 Mohs | ||

| 7 | Thermal Expansion | 0.5*10-6 | ||

| 2 | Chemical Properties | |||

| fused silica sand/grains/granular | fused silica powder/flour | |||

| 2.1 | SiO2 | >99.9% | >99.9% | |

| 2.2 | Al2O3 | <100ppm | <500ppm | |

| The finer the power,the higher the Al2O3,as powder is produced by ball mill with Alumina ball. | ||||

| 2.3 | Fe2O3 | <30ppm | <50ppm | |

| 2.4 | TiO2 | <15ppm | <20ppm | |

| 2.5 | MgO | <30ppm | <50ppm | |

| 2.6 | CaO | <30ppm | <50ppm | |

| 2.7 | Alkalies Na2O+K2O |

<60ppm | <100ppm | |

Standard fused silica fractions/Size are Available as follows:

4-10mesh, 10-20 mesh,30-50 mesh, 50-100 mesh,100-200 mesh120 mesh

200 mesh,325 mesh , 400 mesh, 600 mesh, 800 mesh, 1250 mesh, 2500 mesh

Note:the particle size can also be produced as customer's special requirement

We can supply further product information and our technical experience if you request, and are in position

to supply specially designed product according to clients requirement.

4-10mesh, 10-20 mesh,30-50 mesh, 50-100 mesh,100-200 mesh120 mesh

200 mesh,325 mesh , 400 mesh, 600 mesh, 800 mesh, 1250 mesh, 2500 mesh

Note:the particle size can also be produced as customer's special requirement

We can supply further product information and our technical experience if you request, and are in position

to supply specially designed product according to clients requirement.

Fused Silica cearmic consists of sintered quartz glass high purity powder(also named fused silica silica sand,fused silica powder,

fused silica grains,fused silica flour)with a fine pore structure which has an extremely low expansion coefficient

and thus a very good thermal shock resistance.

fused silica grains,fused silica flour)with a fine pore structure which has an extremely low expansion coefficient

and thus a very good thermal shock resistance.

This material exhibits excellent features such as:

1).Higher strength and toughness so the life should be longer with any surface deformation than the fiber reinforced composite material.

2).Low thermal expansion which provides outstanding resistance to the thermal shock.

3).Good mechanical properties at high temperatures

These features ensure this material is best material for use in the fused silica rollers which are typically used in the following applications; insulation parts used widely in furnaces for solar and PDP (plasma display panel), LCD (liquid crystal display) industries, conveyor rollers, crucible for polycrystalline silicon melting.

1).Higher strength and toughness so the life should be longer with any surface deformation than the fiber reinforced composite material.

2).Low thermal expansion which provides outstanding resistance to the thermal shock.

3).Good mechanical properties at high temperatures

Products Category

Contact Us

Name: Frank Wang

Tel: +86 518 8232 6257

Fax: +86 518 8232 6257

Mobile: 008613851265016

E-mail: [email protected]

Skype: renai11

QQ: 1376936868

WeChat: topsurprise

Whatsapp: 008613851265016

Add: 1-715, Shanghai Square, Huiquan Road, Economic and Technological Development Zone, Lianyungang City, Jiangsu, China 222000

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online