Products >> Fused silica for Investment Casting >>

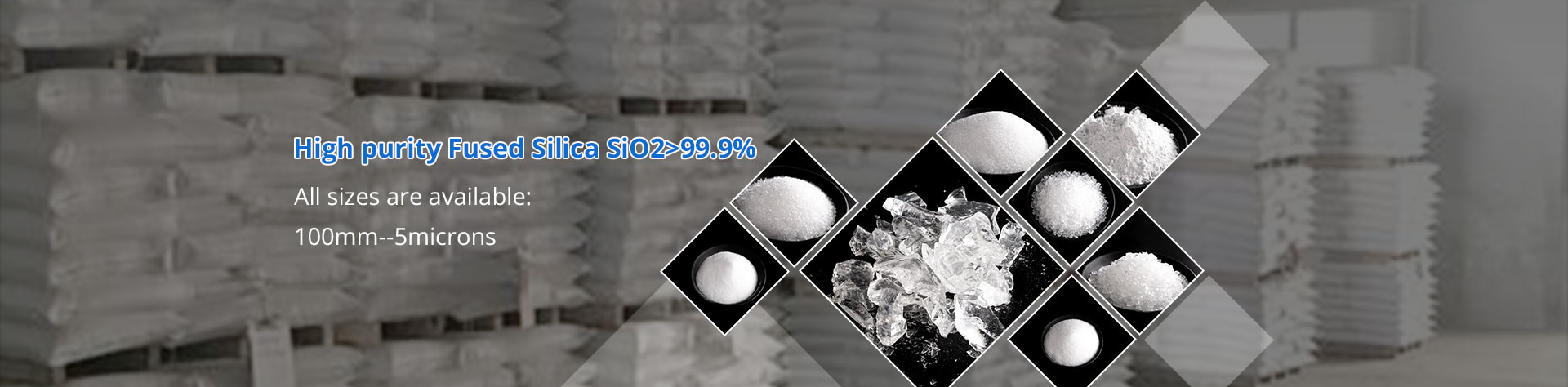

Fused Silica Grains/Flour-Investment casting Grade

- Product No.:Click for Details

- Price(USD):500

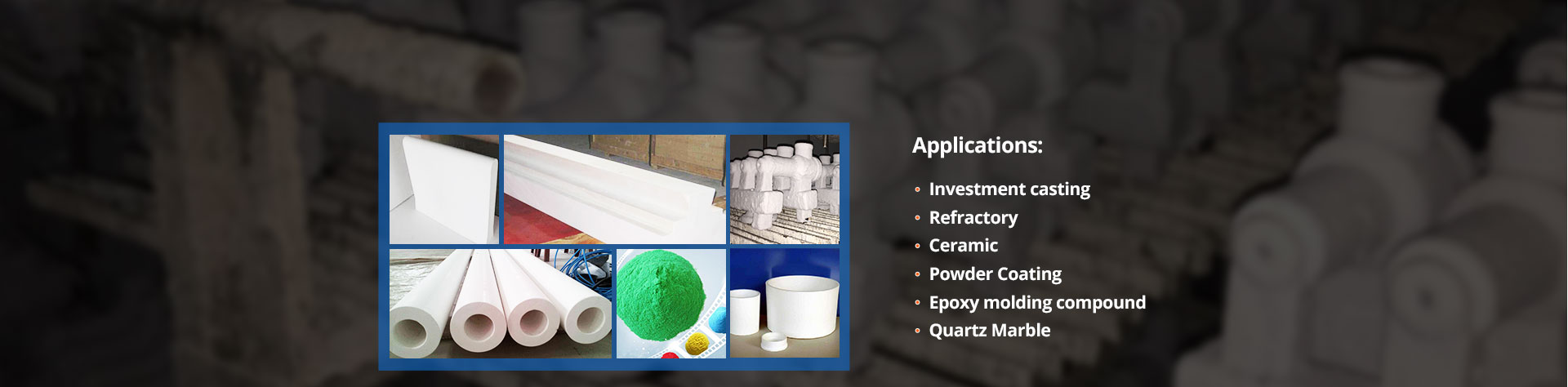

Investment casting, also known as Precision casting or lost-wax casting, is used to make precision products for the industiry of machine,automotive, military, aerospace, medical, commercial, and recreational.

Most investment casting foundries use Zircon Flour for making the primary slurry. Zircon continues to be in short supply and the prices are rising. Many customers began to adopt Fused Silica flour in the dipping and coasting process to make primary slurry, while to use fused silica grains rainfall sander to form a hard ceramic shell.

1) Fused silica decrease in material consumption

Fused Silica's density is 2.21g/cm3,just roughly half of Zircon's density. If Zircon flour is replace 20% in primary slurry batch with Fused Silica, it needs lesser material by weight. For example if slurry mix had 50 kgs of Zircon and try and replace 10 kgs then it would need to add around 6 kgs of Fused Silica flour to achieve the existing viscosities and flow properties.

2) Fused silica increase permeability and porosity

Zircon is very dense. Fused Silica is lighter and does not pack as tightly as Zircon which is why it helps in improving the permeability of your shell. It is also more porous.

3) fused slica ceramic shell is Easier knock-out

Fused Silica knocks out much easier than Zircon or Alumino-Silicates. This is because of the Cristobalite formation while pouring which easily breaks down upon cooling.

4) Faster leaching and shell removal

The moment to add fused silica in the shell it helps in the leaching process and it is much easier to remove shell materials off cavities and holes.

5) Fused Silica price is cheaper

The typical specification sheet of Chem&Size minerals Fused Silica sand,fused silica grains and fused silica powder and fused silica flours for your perusal.

Most investment casting foundries use Zircon Flour for making the primary slurry. Zircon continues to be in short supply and the prices are rising. Many customers began to adopt Fused Silica flour in the dipping and coasting process to make primary slurry, while to use fused silica grains rainfall sander to form a hard ceramic shell.

Some new customers might have main questions as follows:

Question 1.

Can fused silica flour and grains be used to replace Zircon flour and grains?Yes,It's ture.

Question 2.How many percentage of Zircon powder can be replaced by fused silica powder?It is usually 25% and 50% max.

Question 3.How to use fused silica sand? It is same as to use Zircon sand.

Question 4.Why fused silica can instead Zircon?

Fused silica has the following advantages:

1) Fused silica decrease in material consumption

Fused Silica's density is 2.21g/cm3,just roughly half of Zircon's density. If Zircon flour is replace 20% in primary slurry batch with Fused Silica, it needs lesser material by weight. For example if slurry mix had 50 kgs of Zircon and try and replace 10 kgs then it would need to add around 6 kgs of Fused Silica flour to achieve the existing viscosities and flow properties.

2) Fused silica increase permeability and porosity

Zircon is very dense. Fused Silica is lighter and does not pack as tightly as Zircon which is why it helps in improving the permeability of your shell. It is also more porous.

3) fused slica ceramic shell is Easier knock-out

Fused Silica knocks out much easier than Zircon or Alumino-Silicates. This is because of the Cristobalite formation while pouring which easily breaks down upon cooling.

4) Faster leaching and shell removal

The moment to add fused silica in the shell it helps in the leaching process and it is much easier to remove shell materials off cavities and holes.

5) Fused Silica price is cheaper

The typical specification sheet of Chem&Size minerals Fused Silica sand,fused silica grains and fused silica powder and fused silica flours for your perusal.

Fused Silica-Investment Casting Grade

| 1. | Physical Properties | ||

| 1.1 | Composition | SiO2 | |

| 1.2 | Structure | Amorphous | |

| 1.3 | Colour | Transparent or white | |

| 1.4 | Melting Temperature | approx.1750℃ | |

| 1.5 | Specific Gravity | 2.21g/cm3 | |

| 1.6 | Hardness | 7 Mohs | |

| 1.7 | Thermal Expansion | 0.5*10-6 | |

| 2. | Chemical Properties | ||

| Investment Casting Grade | |||

| 2.1 | SiO2 | >99.90% | |

| 2.2 | Al2O3 | <200ppm | |

| The finer the power,the higher the Al2O3,as powder is produced by ball mill with Alumina ball. | |||

| 2.3 | Fe2O3 | <50ppm | |

| 2.4 | TiO2 | <20ppm | |

| 2.5 | MgO | <40ppm | |

| 2.6 | CaO | <40ppm | |

| 2.7 | AlkaliesNa2O+K2O | <100ppm | |

| 3. | Particle Size | Distribution | |

| 10/20mesh | 20/50mesh | 30/50mesh | 50/100mesh | -100mesh | -200mesh | -325mesh | ||

| Mesh | Microns | |||||||

| 8 | 2360 | <2 | ||||||

| 12 | 1700 | 6-25 | ||||||

| 16 | 1180 | 33-50 | ||||||

| 20 | 850 | 25-45 | <1 | <1 | ||||

| 30 | 600 | 13 | 25-40 | 15-30 | ||||

| 40 | 425 | 32-45 | 38-50 | |||||

| 50 | 300 | 15-30 | 20-35 | <13 | ||||

| 70 | 212 | 30-60 | ||||||

| 80 | 180 | 0-11 | <10 | <1 | ||||

| 100 | 150 | 28-51 | <15 | <1 | ||||

| 140 | 106 | 4-16 | 17-40 | <10 | ||||

| 200 | 75 | <2 | 19-34 | <10 | <3 | |||

| 325 | 45 | 14-30 | 15-30 | 4-11 | ||||

| Pan | <3 | <2 | <2 | <1 | 4-20 | 70-80 | 86-97 | |

*Pan designates the percentage of fused silica passing the last reported screen for each size.

4. Dust Removal

Investment casting grade fused silica is treated by dust removal equipment, so that this grade fused silica dust is in the lowest level.

The difference between common grade fused silica and investment grade fused silica.

4.1 Non Dust Removal fused silica

4.2.Dust Removed fused silica for Investment Casting

Products Category

Contact Us

Name: Frank Wang

Tel: +86 518 8232 6257

Fax: +86 518 8232 6257

Mobile: 008613851265016

E-mail: [email protected]

Skype: renai11

QQ: 1376936868

WeChat: topsurprise

Whatsapp: 008613851265016

Add: 1-715, Shanghai Square, Huiquan Road, Economic and Technological Development Zone, Lianyungang City, Jiangsu, China 222000

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online