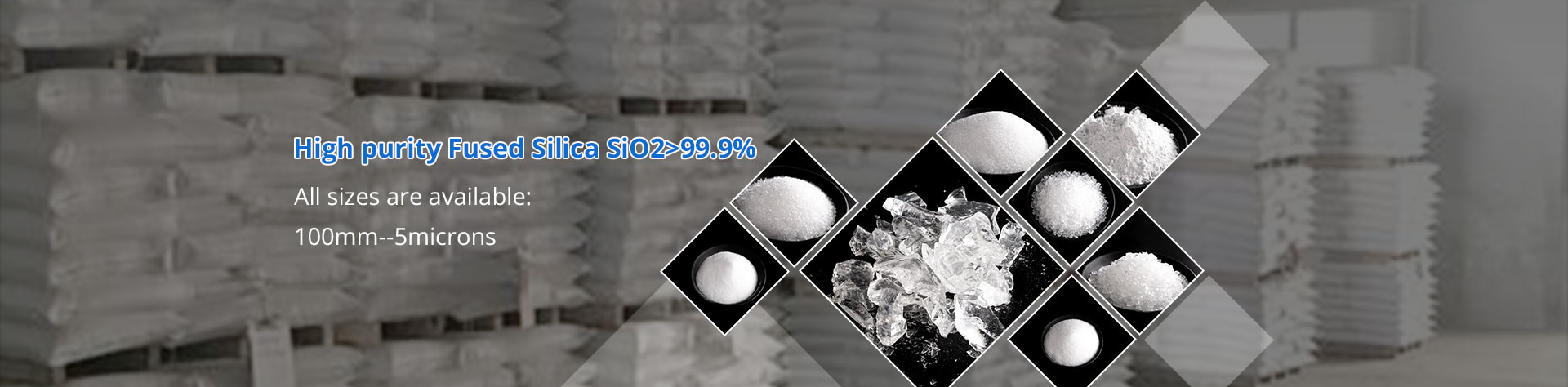

Products >> Fused silica for Investment Casting >>

fused silica grains (stuccos) and powders (flours) for the investment casting

- Product No.:202111391844

- Price(USD):USD550/MT

Chemsize Fused silica is electrically fused high purity silica produced at fusion and processing facility located in China Lianyungang .

Our fused silica products are specially engineered grains and powders designed for use in foundry, refractory, investment casting and other special applications.

Chemsize assures that customers will always receive the highest quality material.

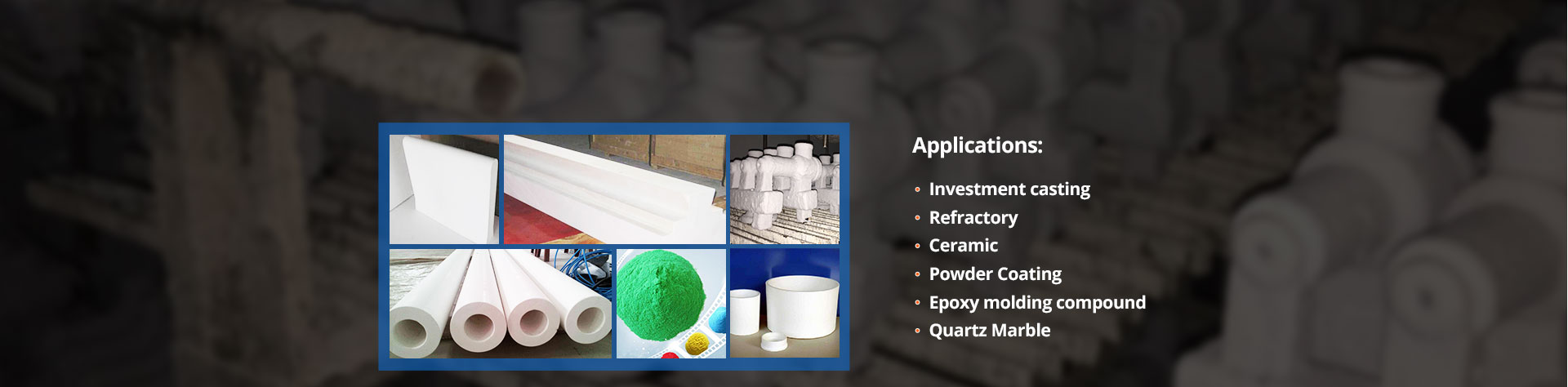

FUSED SILICA FOR INVESTMENT CASTING / REFRACTORY APPLICATIONS

Chemsize produces several grades of coarse fused silica grains (stuccos) and powders (flours) for the investment casting and refractory industries. Due to fused silica’s low thermal conductivity and excellent thermal shock resistance, it is widely used in both industries.

Chemsize makes several standard grain size distributions for both applications.

These are produced by the blending of several tightly controlled fractions.

Dust removal is also given high priority for fluid bed/rainfall sander applications.

Chemsize is capable of producing powders with several different particle size distributions, by utilizing several ball mills on site. This allows the flexibility to

produce material with a broad range of particle size distributions. Particle sizing is controlled using the most up-to-date particle size analyzers.

Chemsize quality control/assurance laboratory has all of the state-of-the-art equipment necessary for testing fused silica grains and powders.

Routinely, the laboratory is capable of performing the following tests: Test sieve analysis, pH, magnetics, atomic absorption spectroscopy, Microtrac p.s.d, B.E.T.

surface area and many others.

Fused Silica grains fused silica powder -Investment Casting Grade

CHEMICAL ANALYSIS

CHEMICAL ANALYSIS

| 1. | Physical Properties | ||

| 1.1 | Composition | SiO2 | |

| 1.2 | Structure | Amorphous | |

| 1.3 | Colour | Transparent or white | |

| 1.4 | Melting Temperature | approx.1750℃ | |

| 1.5 | Specific Gravity | 2.21g/cm3 | |

| 1.6 | Hardness | 7 Mohs | |

| 1.7 | Thermal Expansion | 0.5*10-6 | |

| 2. | Chemical Properties | ||

| Investment Casting Grade | |||

| 2.1 | SiO2 | >99.90% | |

| 2.2 | Al2O3 | <200ppm | |

| The finer the power,the higher the Al2O3,as powder is produced by ball mill with Alumina ball. | |||

| 2.3 | Fe2O3 | <50ppm | |

| 2.4 | TiO2 | <20ppm | |

| 2.5 | MgO | <40ppm | |

| 2.6 | CaO | <40ppm | |

| 2.7 | AlkaliesNa2O+K2O | <100ppm | |

| 3. | Particle Size | Distribution | |

Particle size distribution:PSD

| 10/20 | 20/50 | 30/50 | 50/100 | -100 | -200 | -325mesh | ||

| Mesh | Microns | |||||||

| 8 | 2360 | <2 | ||||||

| 12 | 1700 | 6-25 | ||||||

| 16 | 1180 | 33-50 | ||||||

| 20 | 850 | 25-45 | <1 | <1 | ||||

| 30 | 600 | 13 | 25-40 | 15-30 | ||||

| 40 | 425 | 32-45 | 38-50 | |||||

| 50 | 300 | 15-30 | 20-35 | <13 | ||||

| 70 | 212 | 30-60 | ||||||

| 80 | 180 | 0-11 | <10 | <1 | ||||

| 100 | 150 | 28-51 | <15 | <1 | ||||

| 140 | 106 | 4-16 | 17-40 | <10 | ||||

| 200 | 75 | <2 | 19-34 | <10 | <3 | |||

| 325 | 45 | 14-30 | 15-30 | 4-11 | ||||

| Pan | <3 | <2 | <2 | <1 | 4-20 | 70-80 | 86-97 | |

Custom sizes are also available.

*Pan designates the percentage of fused silica passing the last reported screen for each size.

Products Category

Contact Us

Name: Frank Wang

Tel: +86 518 8232 6257

Fax: +86 518 8232 6257

Mobile: 008613851265016

E-mail: [email protected]

Skype: renai11

QQ: 1376936868

WeChat: topsurprise

Whatsapp: 008613851265016

Add: 1-715, Shanghai Square, Huiquan Road, Economic and Technological Development Zone, Lianyungang City, Jiangsu, China 222000

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online