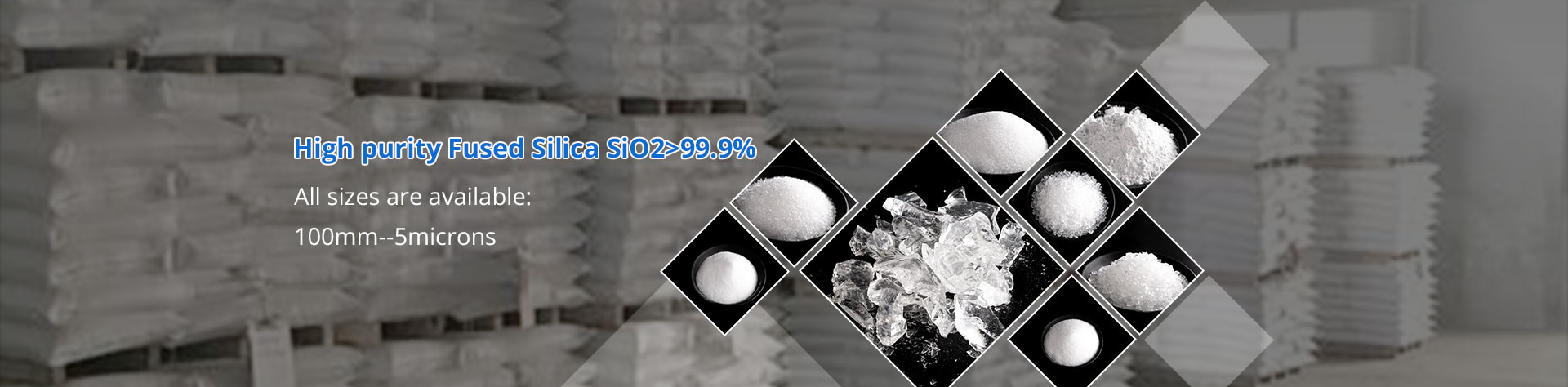

Products >> Fused silica for Investment Casting >>

Fused Silica Flour and Sands offer a high quality ceramic shell and final cast item

- Product No.:2021112174516

- Price(USD):USD550/MT

Fused silica is an amorphous siliceous glass produced by high temperature fusion of high quality crystalline silica(quartz). This fusion produces a substance characterised by very low thermal expansion and a high resistance to temperature and thermal shock.

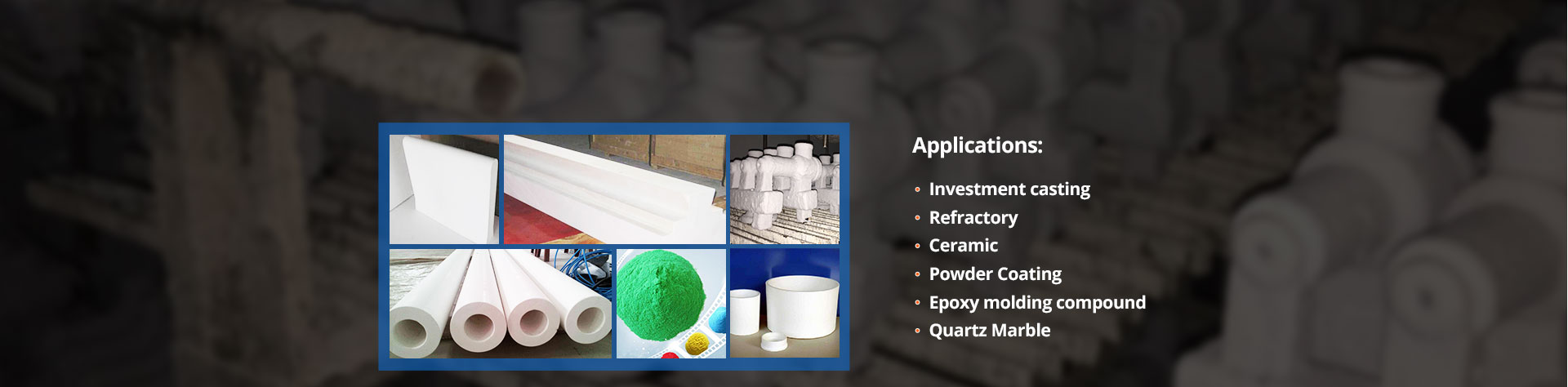

Fused silica is employed in a variety of industrial applications including foundry (investment casting slurry and stucco, and mould release agent), refractory and ceramic (crucibles, saggars, rollers, pouring cups,ceramic cores, gas fire radiants and items for steel, non-ferrous metal and glass industries), and filler (electronic and adhesives).

Chemsize realised early on that the secret of manufacturing investment powder lay in the quality of the raw materials available.

The company has carried out an extensive global sourcing project and has located what it considers to be some of the highest quality refractories so far made available to investment foundries. These include Fused Silica produced from quartz of exceptional purity with an SiO2 content of 99.9%. The source also has particularly low iron, potassium and sodium oxides and such a low trace element content to fall well within Aerospace specifications.

Fused Silica-Investment Casting Grade

| 1. | Physical Properties | ||

| 1.1 | Composition | SiO2 | |

| 1.2 | Structure | Amorphous | |

| 1.3 | Colour | Transparent or white | |

| 1.4 | Melting Temperature | approx.1750℃ | |

| 1.5 | Specific Gravity | 2.21g/cm3 | |

| 1.6 | Hardness | 7 Mohs | |

| 1.7 | Thermal Expansion | 0.5*10-6 | |

| 2. | Chemical Properties | ||

| Investment Casting Grade | |||

| 2.1 | SiO2 | >99.90% | |

| 2.2 | Al2O3 | <200ppm | |

| The finer the power,the higher the Al2O3,as powder is produced by ball mill with Alumina ball. | |||

| 2.3 | Fe2O3 | <50ppm | |

| 2.4 | TiO2 | <20ppm | |

| 2.5 | MgO | <40ppm | |

| 2.6 | CaO | <40ppm | |

| 2.7 | AlkaliesNa2O+K2O | <100ppm | |

| 3. | Particle Size | Distribution | |

| 10/20mesh | 20/50mesh | 30/50mesh | 50/100mesh | -100mesh | -200mesh | -325mesh | ||

| Mesh | Microns | |||||||

| 8 | 2360 | <2 | ||||||

| 12 | 1700 | 6-25 | ||||||

| 16 | 1180 | 33-50 | ||||||

| 20 | 850 | 25-45 | <1 | <1 | ||||

| 30 | 600 | 13 | 25-40 | 15-30 | ||||

| 40 | 425 | 32-45 | 38-50 | |||||

| 50 | 300 | 15-30 | 20-35 | <13 | ||||

| 70 | 212 | 30-60 | ||||||

| 80 | 180 | 0-11 | <10 | <1 | ||||

| 100 | 150 | 28-51 | <15 | <1 | ||||

| 140 | 106 | 4-16 | 17-40 | <10 | ||||

| 200 | 75 | <2 | 19-34 | <10 | <3 | |||

| 325 | 45 | 14-30 | 15-30 | 4-11 | ||||

| Pan | <3 | <2 | <2 | <1 | 4-20 | 70-80 | 86-97 | |

*Pan designates the percentage of fused silica passing the last reported screen for each size.

Products Category

Contact Us

Name: Frank Wang

Tel: +86 518 8232 6257

Fax: +86 518 8232 6257

Mobile: 008613851265016

E-mail: [email protected]

Skype: renai11

QQ: 1376936868

WeChat: topsurprise

Whatsapp: 008613851265016

Add: 1-715, Shanghai Square, Huiquan Road, Economic and Technological Development Zone, Lianyungang City, Jiangsu, China 222000

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online