Products >> Fused silica for Investment Casting >>

fused silica sand and powder for investment casting/light-metal foundry

- Product No.:20211014195759

- Price(USD):USD550/MT

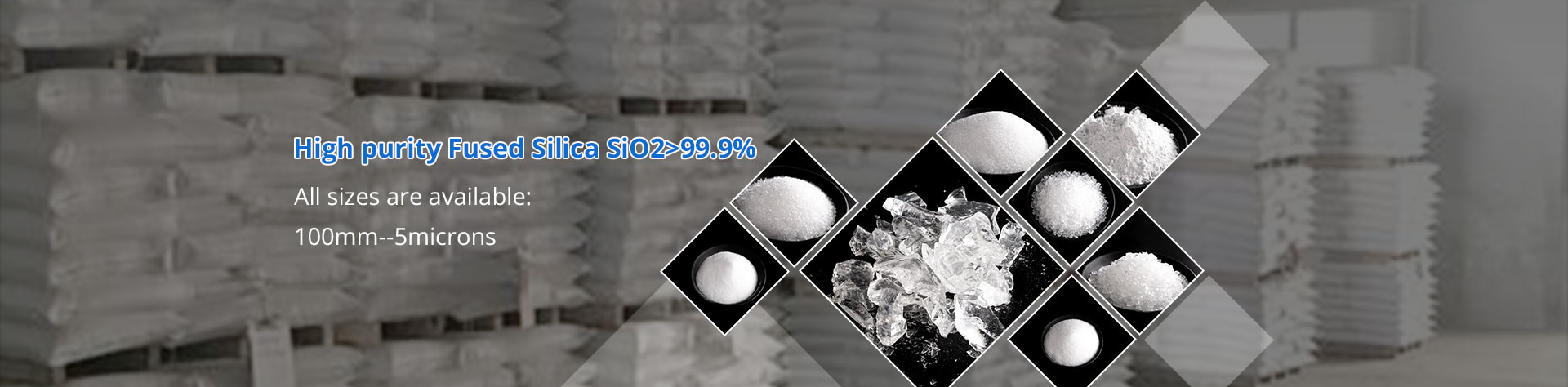

what is Fused silica sand:

During the melting process of quartz sand above temperatures of 1700 °C, fused fused silica develops which contains SiO2 a amorphous modification once it is solidified.

The low extenion value is an advantage (< 0.1 percent, see Sand expansion). Thanks to this favorable behavior, fused-silica sand can be used as basic molding material for reducing sand expansion defects. It has to be take into consideration that already at temperatures of 1300 °C a slight sintering (see Sintering) sets in. This is the reason why it is used nearly exclusively in the area of light-metal foundry.

Fused silica spec:

3. Particle Size Distribution

*Pan designates the percentage of fused silica passing the last reported screen for each size.

Fused silica spec:

| 1. | Physical Properties | ||

| 1.1 | Composition | SiO2 | |

| 1.2 | Structure | Amorphous | |

| 1.3 | Colour | Transparent or white | |

| 1.4 | Melting Temperature | approx.1750ºC | |

| 1.5 | Specific Gravity | 2.21g/cm3 | |

| 1.6 | Hardness | 7 Mohs | |

| 1.7 | Thermal Expansion | 0.5*10-6 | |

2. |

Chemical Properties |

||

| Grade A Plus | |||

| 2.1 | SiO2 | >99.9% | |

| 2.2 | Al2O3 | <100ppm | |

| The finer the power,the higher the Al2O3,as powder is produced by ball mill with Alumina ball. | |||

| 2.3 | Fe2O3 | <30ppm for grains <60ppm for powder |

|

| 2.4 | CaO | <15ppm | |

| 2.5 | Na2O | <15ppm | |

| 2.6 | K2O | <15ppm | |

3. Particle Size Distribution

| Standard | |||||||

| 10-20 | 30-50 | 50-100 | -120 | -200 | -325 | ||

| Mesh | Microns | ||||||

| +8 | 2360 | <2 | |||||

| +12 | 1700 | 6-25 | |||||

| +16 | 1180 | 33-50 | |||||

| +20 | 850 | 25-45 | <1 | ||||

| +30 | 600 | 13 | 25-40 | ||||

| +40 | 425 | 32-45 | |||||

| +50 | 300 | 15-30 | <13 | ||||

| +70 | 212 | 30-60 | |||||

| +80 | 180 | 0-11 | <1 | ||||

| +100 | 150 | 28-51 | <10 | <1 | |||

| +140 | 106 | 4-16 | 7-13 | <10 | |||

| +200 | 75 | <2 | 10-15 | <10 | <3 | ||

| +325 | 45 | 14-20 | 15-30 | 4-11 | |||

| Pan | <3 | <2 | <1 | 45-55 | 70-80 | 86-97 | |

Previous Product:fused silica powder 200mesh 325mesh for ceramic shell slurry

Next Product:Fused Silica Grains/Flour-Investment casting Grade

Products Category

Contact Us

Name: Frank Wang

Tel: +86 518 8232 6257

Fax: +86 518 8232 6257

Mobile: 008613851265016

E-mail: [email protected]

Skype: renai11

QQ: 1376936868

WeChat: topsurprise

Whatsapp: 008613851265016

Add: 1-715, Shanghai Square, Huiquan Road, Economic and Technological Development Zone, Lianyungang City, Jiangsu, China 222000

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online