Products >> Fused silica for Investment Casting >>

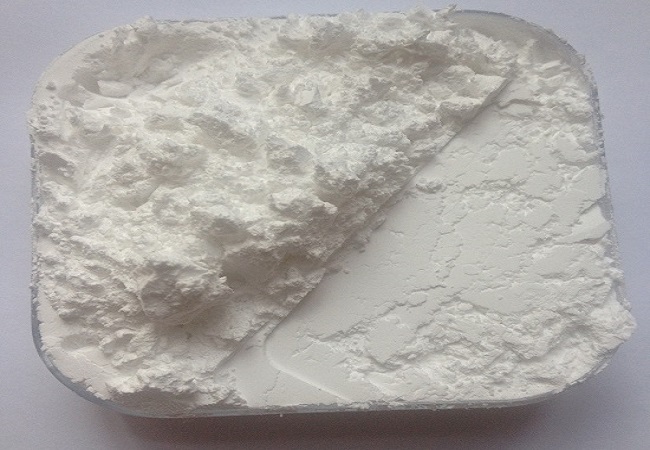

fused silica powder 200mesh 325mesh for ceramic shell slurry

- Product No.:2021101575621

- Price(USD):USD550/MT

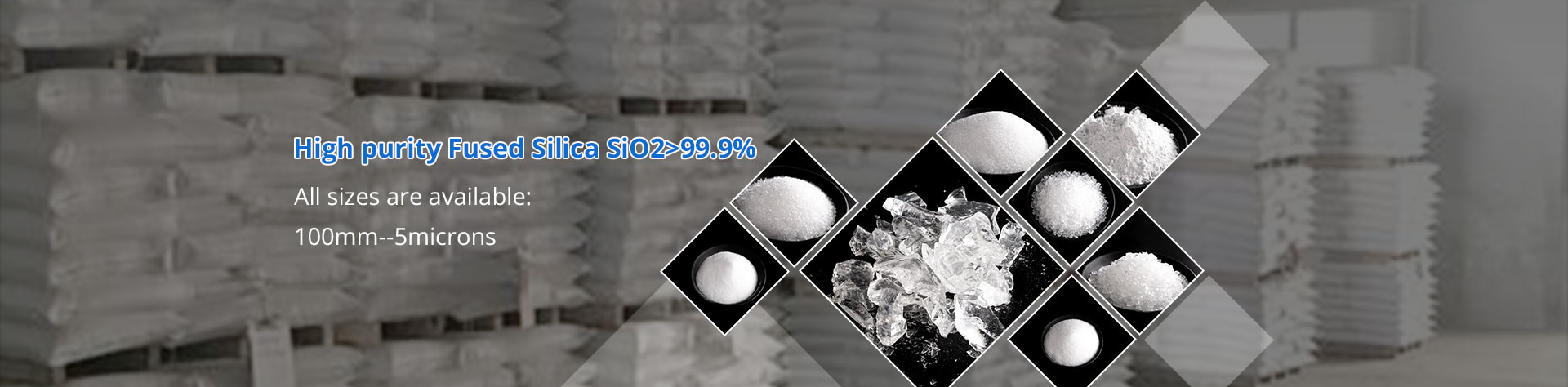

Chemsize fused silica is an high purity amorphous silicon doxide which is made by electrically fused high purity acid wasted silica. Fused silica has a low thermal conductivity and excellent thermal shock resistance. These properties, along with its low density, make it an excellent refractory for use in a ceramic shell mold. Chemsize fused silica is available in flour and granular forms.

Chemsize fused silica can be used throughout the ceramic shell. Shells constructed with fused silica hold their dimensions better and are not prone to hot deformation or bulging. Shell knockout is also easier with fused silica refractories.

Primcoat Binder is mixed with either -120mesh or 200mesh and used in conjunction with 50-100 or 30-50mesh to build ceramic shells for Lost Wax Casting.

This is the video on Youtube aboutCeramic shell slurry & first fused silica coat.D ipping a wax on a ceramic shell slurry drum, until its completely wet, then letting it drip excess slurry, to ad the first coat of fused silica

Fused silica for investment casting spec:

3. Particle Size Distribution

*Pan designates the percentage of fused silica passing the last reported screen for each size.

This is the video on Youtube about

Fused silica for investment casting spec:

| 1. | Physical Properties | ||

| 1.1 | Composition | SiO2 | |

| 1.2 | Structure | Amorphous | |

| 1.3 | Colour | Transparent or white | |

| 1.4 | Melting Temperature | approx.1750ºC | |

| 1.5 | Specific Gravity | 2.21g/cm3 | |

| 1.6 | Hardness | 7 Mohs | |

| 1.7 | Thermal Expansion | 0.5*10-6 | |

2. |

Chemical Properties |

||

| Fused silica investment casting Grade | |||

| 2.1 | SiO2 | >99.85% | |

| 2.2 | Al2O3 | <150ppm | |

| The finer the power,the higher the Al2O3,as powder is produced by ball mill with Alumina ball. | |||

| 2.3 | Fe2O3 | <60ppm for grains <100ppm for powder |

|

| 2.4 | CaO | <15ppm | |

| 2.5 | Na2O | <15ppm | |

| 2.6 | K2O | <15ppm | |

3. Particle Size Distribution

| Standard | |||||||

| 10-20 | 30-50 | 50-100 | -120 | -200 | -325 | ||

| Mesh | Microns | ||||||

| +8 | 2360 | <2 | |||||

| +12 | 1700 | 6-25 | |||||

| +16 | 1180 | 33-50 | |||||

| +20 | 850 | 25-45 | <1 | ||||

| +30 | 600 | 13 | 25-40 | ||||

| +40 | 425 | 32-45 | |||||

| +50 | 300 | 15-30 | <13 | ||||

| +70 | 212 | 30-60 | |||||

| +80 | 180 | 0-11 | <1 | ||||

| +100 | 150 | 28-51 | <10 | <1 | |||

| +140 | 106 | 4-16 | 7-13 | <10 | |||

| +200 | 75 | <2 | 10-15 | <10 | <3 | ||

| +325 | 45 | 14-20 | 15-30 | 4-11 | |||

| Pan | <3 | <2 | <1 | 45-55 | 70-80 | 86-97 | |

Products Category

Contact Us

Name: Frank Wang

Tel: +86 518 8232 6257

Fax: +86 518 8232 6257

Mobile: 008613851265016

E-mail: [email protected]

Skype: renai11

QQ: 1376936868

WeChat: topsurprise

Whatsapp: 008613851265016

Add: 1-715, Shanghai Square, Huiquan Road, Economic and Technological Development Zone, Lianyungang City, Jiangsu, China 222000

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online